Welcome to Minghui's official website - PCB Manufacturing's 10-year major brand

Mobile phone:19168988006wu@mhfpcb.com

Welcome to Minghui's official website - PCB Manufacturing's 10-year major brand

Mobile phone:19168988006wu@mhfpcb.com

We are committed to providing one-stop diversified services to global customers,

In order to meet customers' requirements for high quality and efficiency, Minghui Soft and Hard Circuits has built a one-stop production factory in Shenzhen

Factory Visit

Factory Visit

Factory Visit

Factory Visit

Jiantao/Shengyi A-grade board, Guangxin/Sun Ink UL/ISO/9001/14001 certification

Samples are shipped 24 hours a day, delivered in batches and batches, and shipped via SF Express

Sales engineers provide one-on-one service with dedication, patience, attention to detail, and professionalism

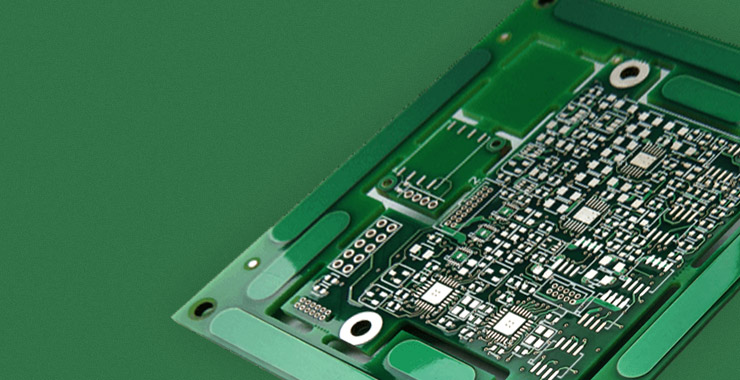

Process flow of single-sided PCB board: cutting and edge grinding → drilling → outer layer graphics → (full board gold plating) → etching → inspection → silk screen solder mask → (hot air leveling) → silk screen characters → shape processing → testing → inspection. Double sided PCB board process flow: cutting and grinding edges → drilling → copper sinking and thickening → outer layer graphics → tin plating, etching and tin removal → secondary drilling → inspection → silk screen solder mask → gold-plated plug → hot air leveling → silk screen characters → shape processing → testing → inspection.

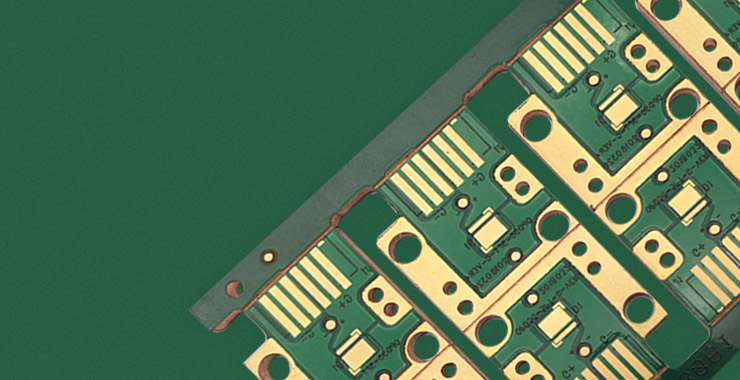

Prepare data: including substrate, conductive data, insulation materials, etc. Design circuit diagram: Design a multi-layer PCB circuit diagram according to the requirements. Creating Inner Circuit: Transfer the circuit diagram onto the inner board and then etch the circuit. Making outer circuit: Cover an insulation layer on the inner board, and then design and etch the circuit on the outer layer. Layering: Stacking multiple layers of boards together and then laminating them to tightly bond the circuits of each layer. Drilling: Drilling holes on multi-layer boards to connect the layers together. Welding components: Welding electronic components onto a PCB. Quality inspection: Check the quality of multi-layer PCBs to ensure they meet the requirements. Packaging: Pack multi-layer PCBs for transportation or use.

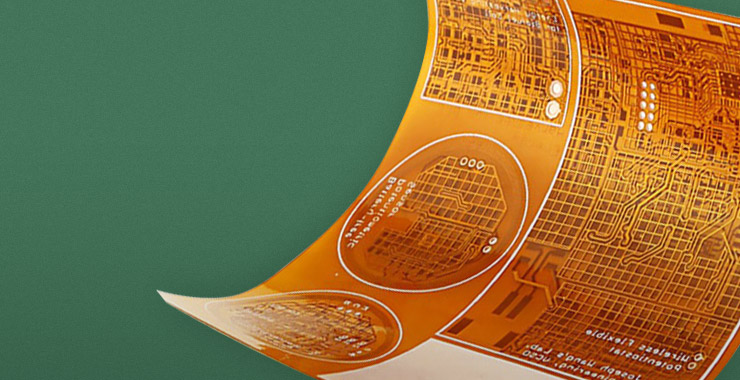

Substrate production: The substrate mainly consists of copper foil, adhesive, and PI (polyimide), and can be classified into single-sided and double-sided substrates. Data with only one copper foil is considered a single-sided substrate, while data with two copper foils is considered a double-sided substrate. Exposure: The transfer of circuit graphics onto the board through the action of a dry film is usually carried out using a photosensitive method. After the exposure is completed, the circuit of the FPC board is basically formed. PI Etching: Under certain temperature conditions, etching solution is uniformly sprayed onto the surface of copper foil through a nozzle, undergoes oxidation-reduction reaction with copper, and then undergoes film removal treatment to form a circuit. Hole opening: The purpose of hole opening is to form the original conductor line and the interconnection line between layers. Hole opening technology is commonly used for the conductive connection between the upper and lower layers of double-layer FPC. Testing: After the production is completed, it is necessary to conduct testing to screen out unqualified FPC boards and ensure that the FPC maintains good performance in application.

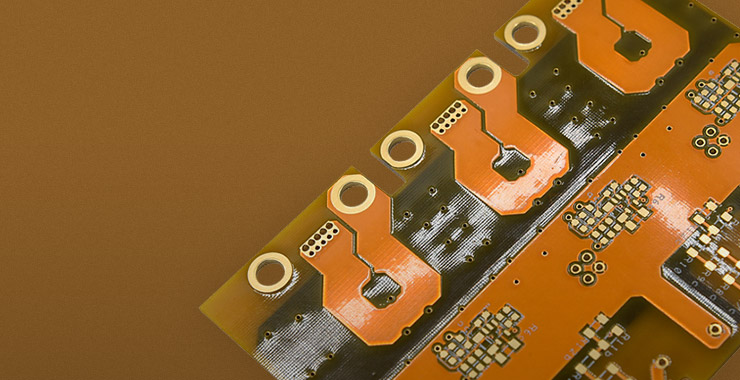

Board preparation: Select appropriate soft and hard data for cutting and trimming. Hot pressing: Overlay soft and hard data in a certain order and place them in a hot press machine for heating and pressing. Pressure control: Based on the characteristics and requirements of soft and hard data, control the pressure of the hot press machine to avoid unstable sheet quality caused by excessive or insufficient pressure.

Dedicated to providing one-stop PCBA services for global R&D enterprises

The application of PCB in the field of communication is very extensive. The PCBs used in the field of communication can be roughly divided into two main types: communication devices and communication terminals.

The application in the field of consumer electronics is very extensive. Consumer electronics includes various products such as computers, mobile phones, televisions, speakers, cameras, etc., all of which require electronic devices to achieve their functions.

PCB Widely used in automotive electronics, including four major systems: power control system, safety control system, body electronic system, and entertainment communication.

PCB is widely used in the field of medical electronics. Medical electronic devices require high-precision and high reliability circuit boards to support their normal operation, and PCB, as one of the core components of electronic devices, provides necessary circuit boards and electronic components for medical equipment.

PCB The application in the field of industrial interconnection is an important link in realizing the interconnection and intelligent control of industrial equipment.

PCB The application in the field of AI human-computer interaction mainly serves as the hardware foundation of electronic devices, providing necessary circuit boards and electronic components for AI interactive devices to support their normal operation.

The application of PCB in the aerospace field is extensive. Whether it's rockets, satellites, or airplanes, PCBs are needed to implement electronic devices for various functions.

PCB also has a wide range of applications in smart cities. An important support for smart cities is the widespread integration of information technology, and PCB, as the basic component of electronic products, provides hardware support for the construction of smart cities.

Save time on finding factories, assembling patches, and finding materials

High yield rate of 97%

AOI100% Full Test

BGA X-ray Full Test

Response within 60 minutes

Reply within 24 hours

Processed within 48 hours

Samples to be shipped within 24 hours

Small batch shipment within 72 hours

Batch can be shipped in batches

Pearl River Delta's own logistics team

SF Express can cross over and air freight is available

Minghui's latest news, stay ahead of time and know

随着人工智能技术与可穿戴设备的深度融合,AI眼镜市场正迎来快速发展期。作为AI眼镜中的关键组件,柔性电路板(FPC)的性……

View details >>在 2025 年机器人产业快速发展的浪潮中,FPC(柔性印制电路板)作为机器人内部信号传输与部件连接……

View details >>在电子制造行业持续发展的背景下,软硬结合板(刚挠结合板)作为高端互连解决方案,对工艺技术和质量稳定性……

View details >>明辉软硬(深圳)电路科技有限公司在多层板 FPC 制造领域,依托其背后有着多年行业经验沉淀的团队,迅……

View details >>在电子制造行业中,柔性电路板(FPC)及软硬结合板(刚挠结合板)作为关键组件,广泛应用于消费电子、医……

View details >>

Telephone

TOP